Accomplishments

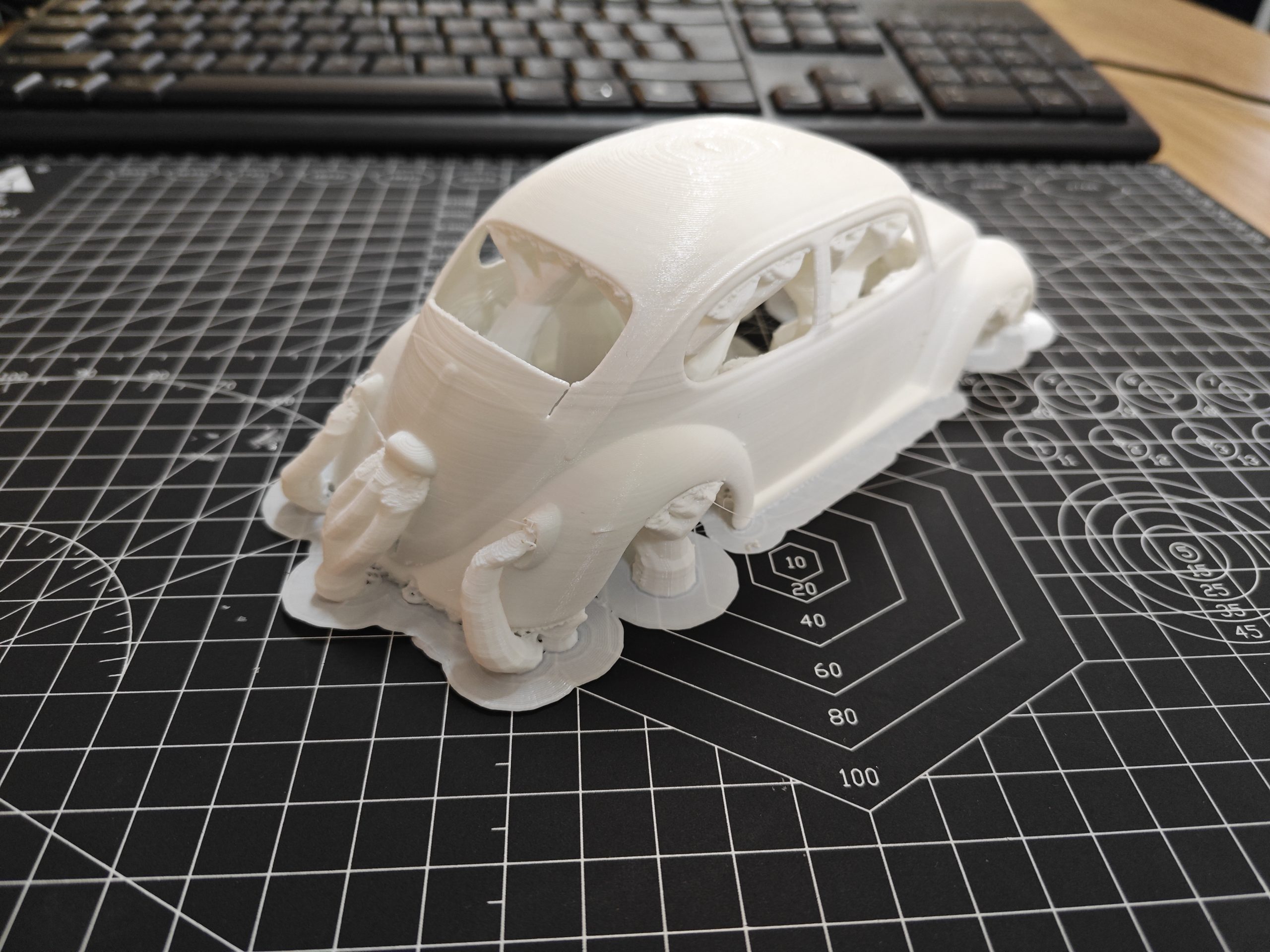

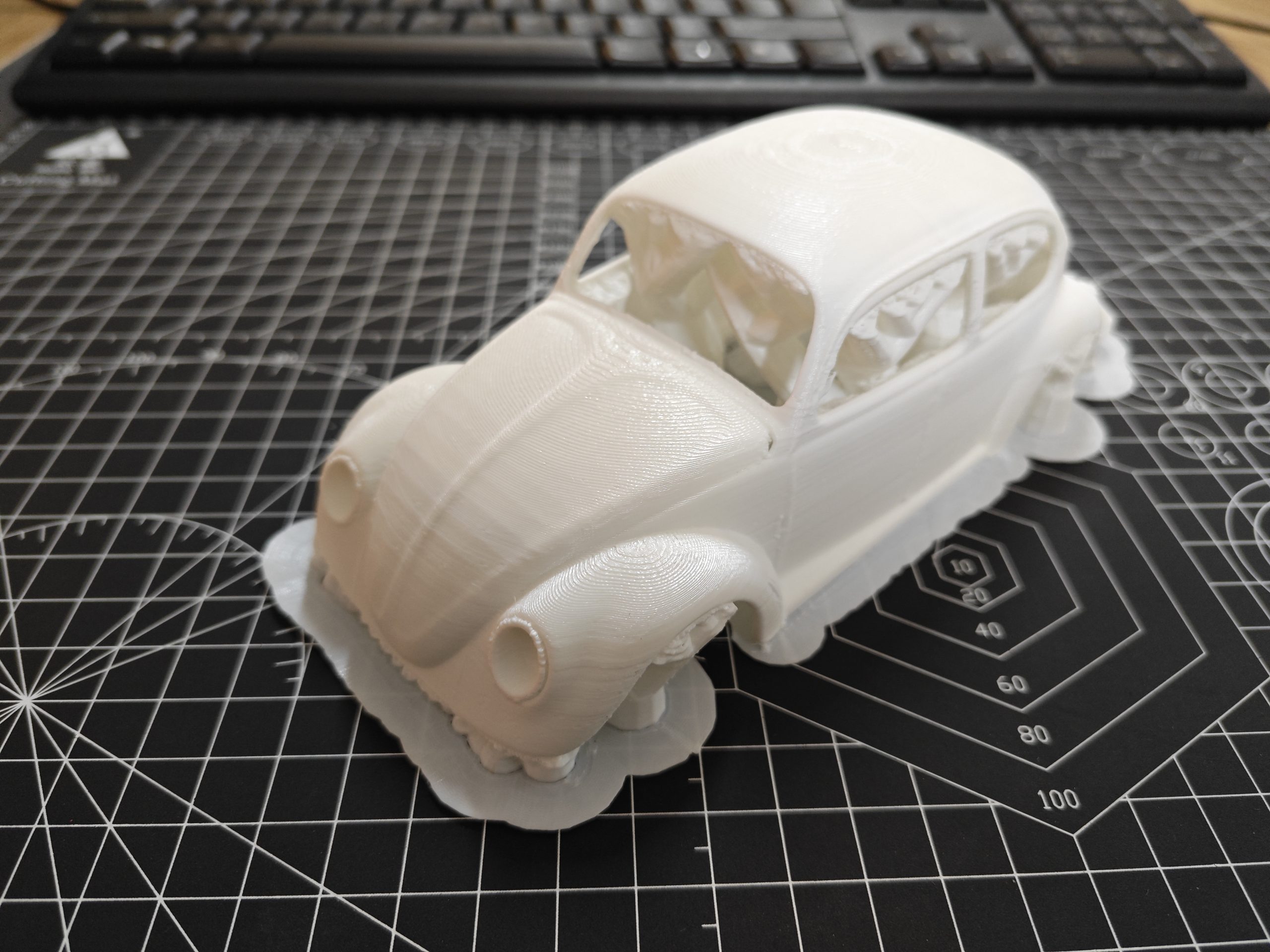

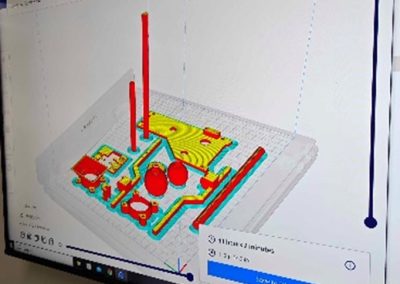

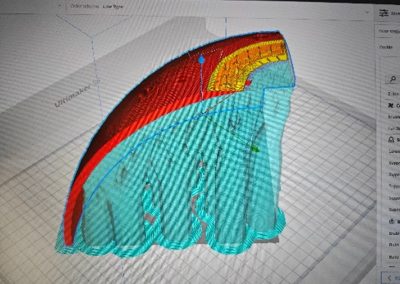

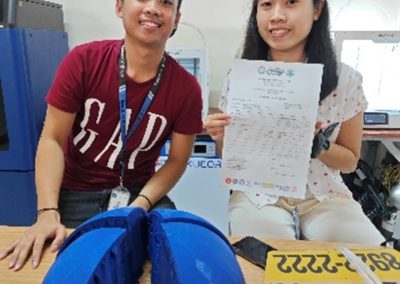

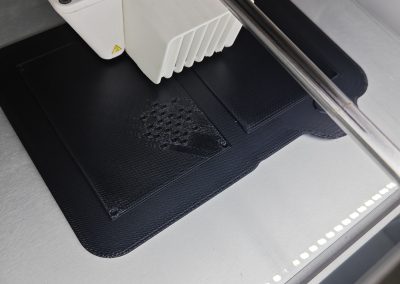

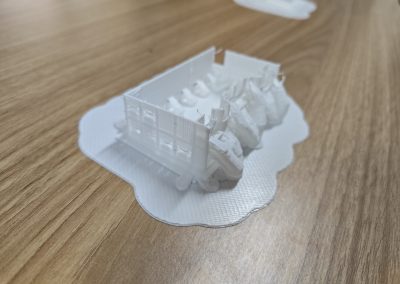

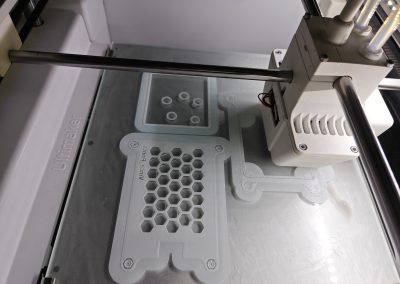

Electronics Engineering students of Universidad De Dagupan visited the laboratory and availed 3D printing services. The model is sliced and normal profile is used. This profile prioritizes speed more than its visuals. The students used this profile since they’ve already planned on post processing the print, making it smooth and also applying paint.

The print is finished after eight hours. The print is somewhat smooth and is acceptable as initial frame for their line tracker. Acetone smoothing is recommended as initial post process step.

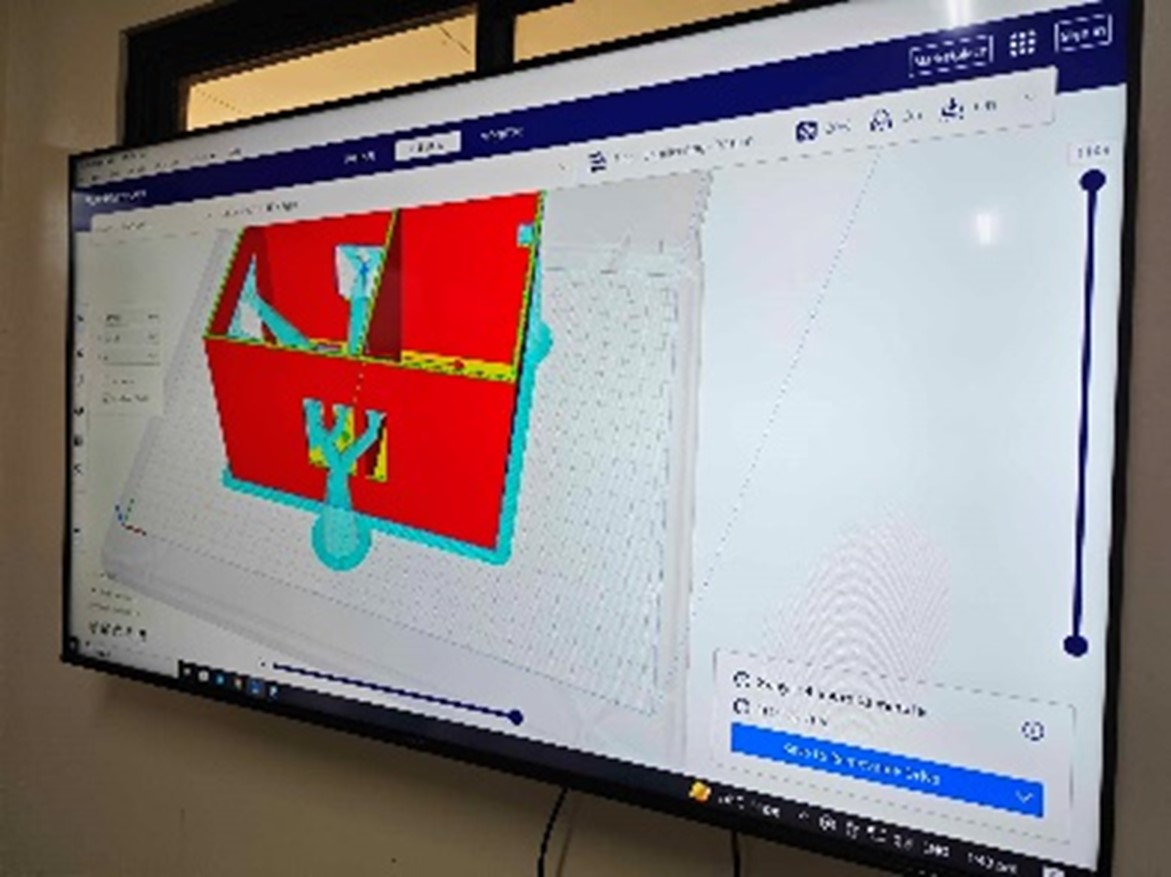

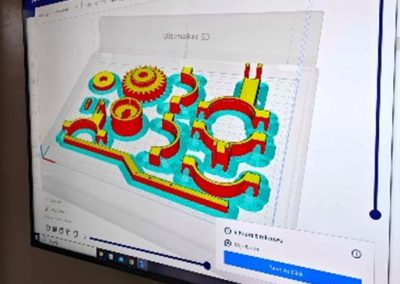

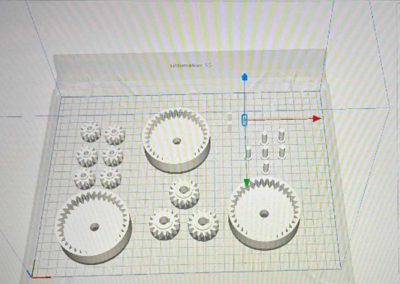

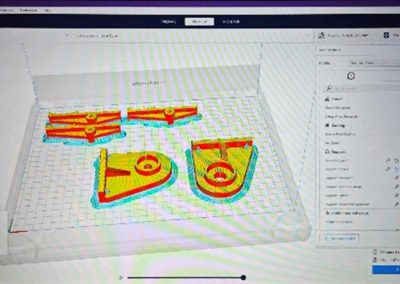

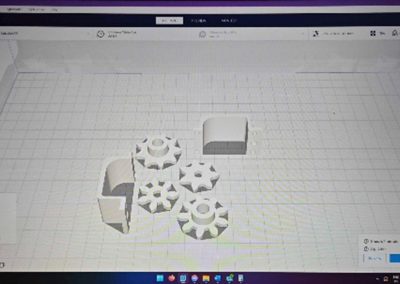

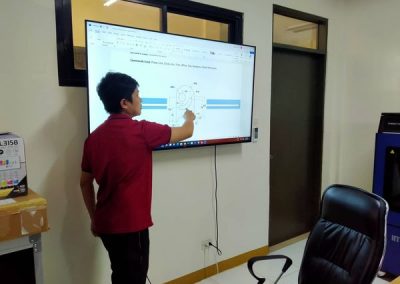

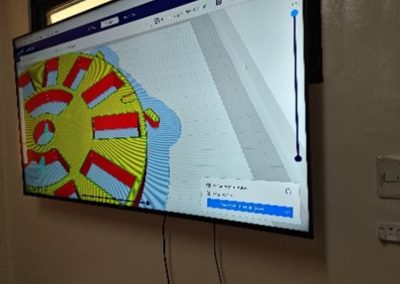

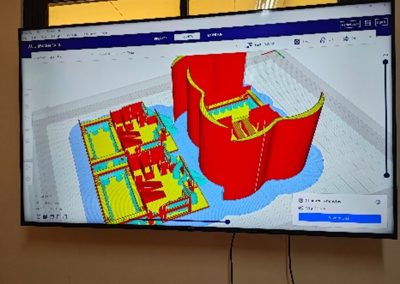

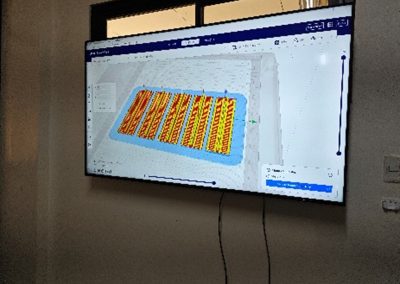

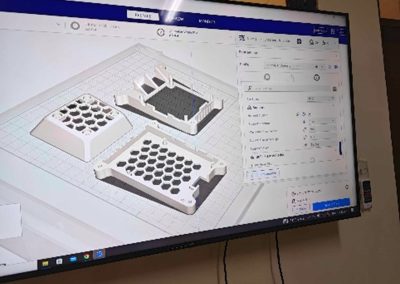

Some of the machines are Manual Transmission Gearbox, Three-speed Automatic Transmission, Conveyor Belt, and Elevator. Below are some of the sliced parts of the machines.

2023

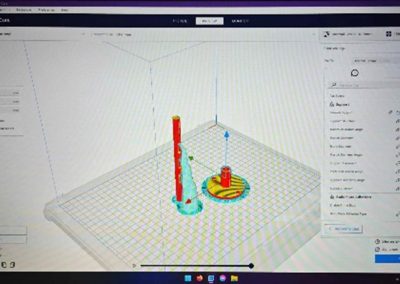

In order to lessen print cost and time, the support used in this project is tree support. Durability of the print is not a problem since infill density is at 20% and marine epoxy will be used to reinforce the print.

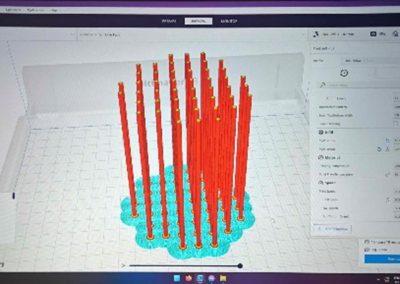

The researchers chose Acrylonitrile Butadiene Styrene (ABS) plastic for their research. This is because ABS plastic is tougher and lighter than PLA, making it a better option for prototyping type of projects. The whole print has lasted for two days.

After the reiteration of their design, their 3D model is sliced and printed. They chose ABS plastic for toughness and lightness since their project should withstand frequent drops two to three feet above ground.

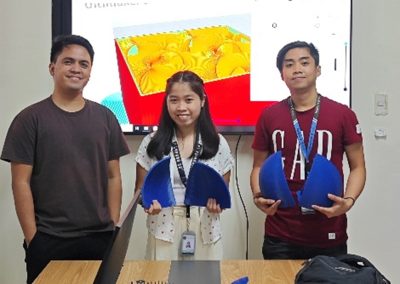

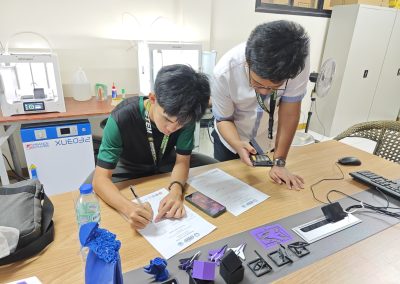

The project took six hours to print. The clients are satisfied on the result and the transaction is concluded.

The product is finished and is tested for tolerances. The magnets are snug fit on the 3D printed object and has shown no significant play. Bolts are threaded perfectly. The project has concluded and the client is satisfied.

Their models are created using the software Sketchup. Initially, their design shows errors due to planes not entirely covered. This is an error commonly found on models which are made in Sketchup. Their models are adjusted to eliminate the errors. Dimensions are also adjusted since their initial dimensions are smaller than the printer nozzle diameter which is 0.4mm. The plastic used is PLA.

Overall, SoFFReL has gained popularity over the past month and became busier. This is the result of information dissemination effort made by different faculty on different departments of CEA. The future is looking good for the laboratory, as time will push everyone towards technological advancements, especially on 3D printing.